Dosing pump kit is a device that precisely inserts or mixes a small number of various reagents into a pipe or well.

Every water treatment solution has a recommended mix ratio, for example APF® has a recommended mix ratio of 0.3-1 ml/hr. of APF® per 1 m3 of water per hour (1,000 liters/hour).

Such as the water in the system has a flow rate of 5 m3 per hour. If APF® is used for sedimentation APF® must be added at a rate of 1.5-5 ml per hour. The chemical pump will be able to precisely fill the APF® reagent at the rate we need.

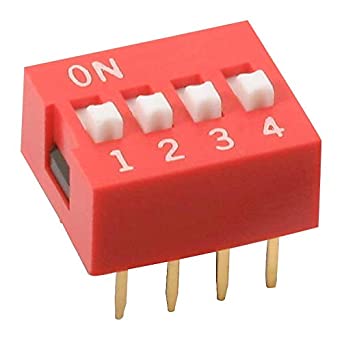

Chemical pump (Dosing pump) can adjust the flow rate of the liquid. This chemical pump has a 4-bit DIP switch to select the fluid flow rate, as in the table below

| Switch #1 |

Switch #2 |

Switch #3 |

Switch #4 |

Flow rate (ml/hr) |

| ON |

OFF |

ON |

ON |

1.25 |

| ON |

OFF |

OFF |

ON |

2.08 |

| ON |

OFF |

ON |

OFF |

4.17 |

| ON |

OFF |

OFF |

OFF |

12.49 |

| ON |

ON |

ON |

ON |

12.49 |

| ON |

ON |

OFF |

ON |

20.80 |

| ON |

ON |

ON |

OFF |

41.55 |

| ON |

ON |

OFF |

OFF |

123.97 |

| OFF |

ON or OFF |

ON or OFF |

ON or OFF |

MAX |

If required more accurate flow rate, the dilution technique can be used to make the Dosing pump kit (chemical pump) have the desired flow rate.

The installation location of the chemical pump (Dosing pump) is recommended to be installed between the water pump and the filter tank. It can be used in conjunction with a static mixer to achieve thorough mixing or can also be installed in front of the pump.

Chemical dosing pump is a small and gave good positive results.

It is designed to pump very precise flow rates of chemicals or substances in the flow of water, steam or gas.

The pump provides an accurate flow rate of chemicals or other products.

by various methods, a measurable amount must be drawn into the chamber and then injected into a hose or tank.

Dosing pumps are used in a wide variety of applications from agriculture to manufacturing to pharmaceutical production.

Chemical pumps are usually relatively small and are powered by a small electric motor or air actuator.

They are controlled by an external control system or generally an internal pump controller that can change the flow rate, on/off functions and the like.

such as alarms and warnings for dry level operation, degassing and low-level of substances.

All dosing pumps are tested using state-of-the-art technology. reliable Through the use of high-quality materials, rigorous laboratory testing and testing, every dosing pump was running at a maximum speed of 6 hours before the final test.

Test certificates with pressure/flow rate diagrams made to customer specifications are available as an option.

The dosing pump kit has a controllable dosing rate used to inject liquids such as additives into the pumping system or mix in low volumes.

Dosing pumps are generally made of plastic. But it can be built from stainless steel and thermoplastic.

The dosing pumps are available in single and double diaphragm designs and are used to transfer hazardous chemicals such as acids, concrete adhesives, coolants and high heat media.

in large chemical pumps Used to transfer fuel, oil, portable water, brine and wastewater such as wastewater and sludge.

Metering Pumps, or Dosing Pumps, are pumps capable of pumping precise amounts of liquid at specified intervals and providing accurate flow rates.

Metering of liquids at a precise flow rate sometimes called “Metering”, the term “Metering Pump”

It depends on the application or the type of pump dispenser. There are also pumps capable of pumping liquids over a greater and more suitable distance which can be found in other types of liquid dispenser pumps.

Metering Pump is used for pumping liquids. Therefore, it is often used to meter chemicals, solutions or other liquids.

For metering pumps, many are designed to allow for high-pressure pumping of liquids. At practically stable flow rates (when averaged over time) there is a wide flow rate tuning range.

The manufacturer has set the maximum pressure range of the pump for each model. To prevent overloading the pump, each model is guaranteed to be able to meter without problems.

The design engineers or users should verify that the adjustment of pressure, temperature and pump components in contact with the liquid and the type of liquid being pumped is correct.

Most metering pumps have pump heads and motors. The liquid is pumped through the pump head through the inlet line and out through the power cable by a motor, an electric motor used to drive the pump head.